Products

Products

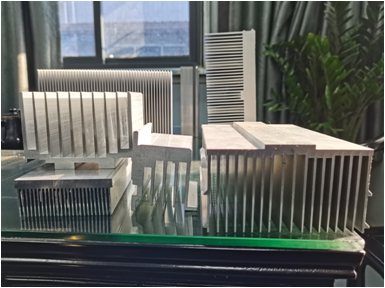

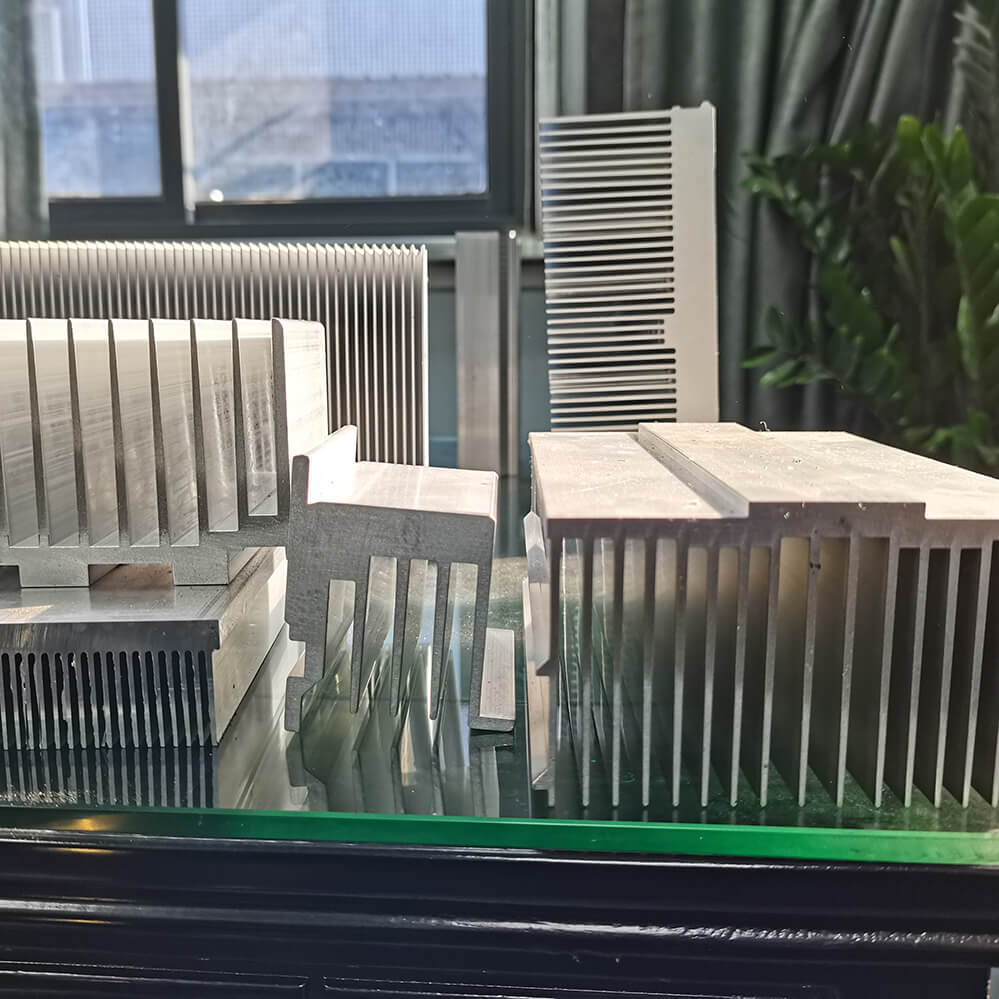

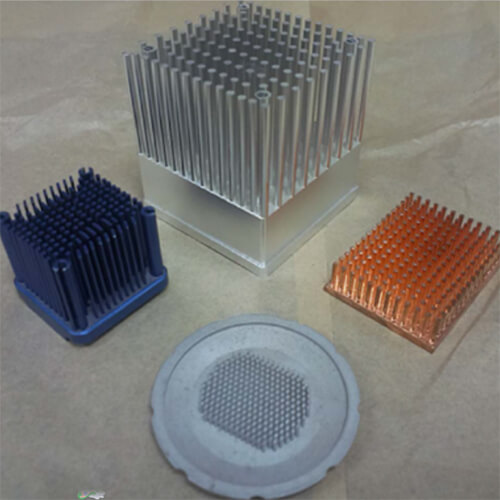

Features of the radiator for the furnace will be aluminum ingot after high temperature heating extruding aluminum rod, and then the aluminum rod injected into the groove mold, make the radiator embryo, and then after processing (CNC, trimming, drilling, tapping, polishing, wire drawing, surface treatment, riveting PIN, packaging, etc.)

Read MoreSend InquiryExcellent thermal aluminum alloy heat sink itself is soft and easy to process, low cost, which is widely used in modern heat dissipation of excellent heat dissipation materials, most of the industry are using 6063 T5 high-quality aluminum, its purity can reach more than 98%.

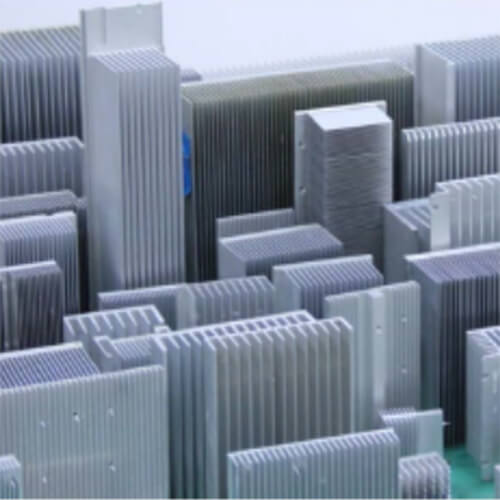

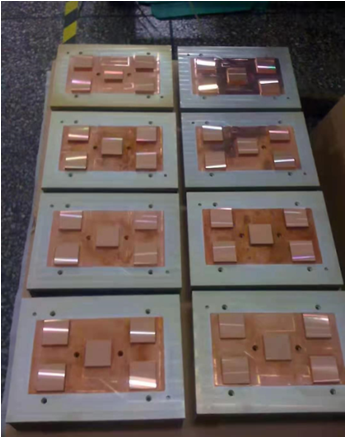

Read MoreSend InquiryAdvantages break through the aluminum extrusion industry in the heat sink blade height and thickness multiple or complex structure of the blade limitations, can produce higher density radiator, can choose different blade material, and the production efficiency of the product is high, the product cost is low

Read MoreSend InquiryThe spade-tooth radiator breaks through the limitation of the thickness and length ratio of the conventional radiator, and can produce a higher density radiator. The blade and the base of the radiator are integrated, there is no problem of interface impedance, and the heat dissipation effect of the radiator is very good. Well, it is close to aluminum extruded heat sink, which is widely used in various types of radiators in photovoltaic industry radiators, electric vehicles, inverters, communications and medical equipment products

Read MoreSend Inquiry