Products

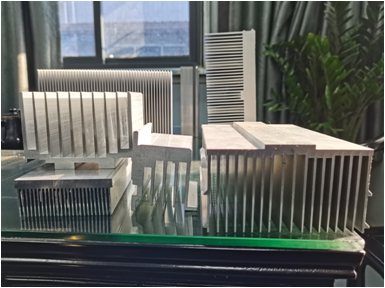

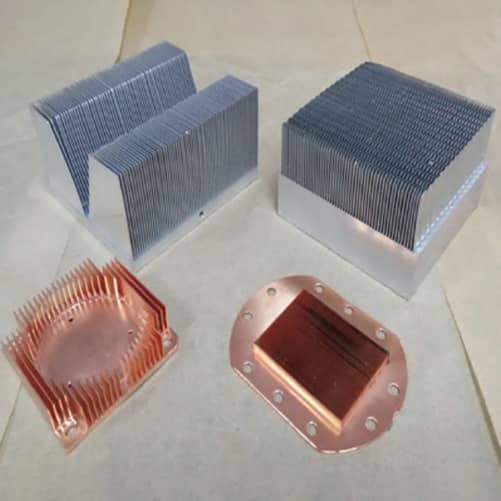

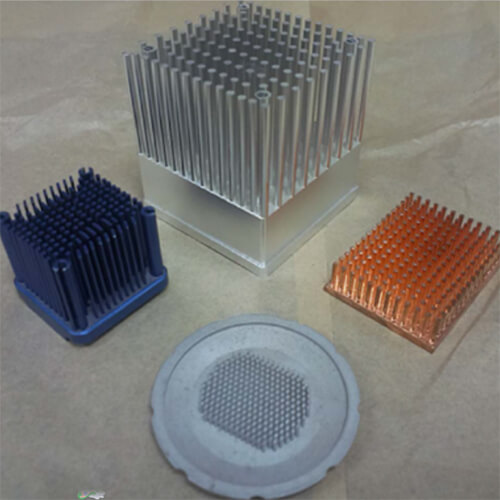

Shovel heat sink

The spade-tooth radiator breaks through the limitation of the thickness and length ratio of the conventional radiator, and can produce a higher density radiator. The blade and the base of the radiator are integrated, there is no problem of interface impedance, and the heat dissipation effect of the radiator is very good. Well, it is close to aluminum extruded heat sink, which is widely used in various types of radiators in photovoltaic industry radiators, electric vehicles, inverters, communications and medical equipment products

Send Inquiry

Product Description

Shovel heat sink

1. Features

The shovel heat sink uses a special knife (shovel) on an aluminum or copper plate to shovel out the blades one by one and erect them.

2 advantages

It breaks through the limitation of the thickness and length ratio of conventional heat sinks, and can produce higher density heat sinks. The blade and the base are integrated, there is no problem of interface impedance, the heat dissipation is very good, close to the aluminum extruded heat sink, and it is widely used Used in the photovoltaic industry, electric vehicles, inverters, communications and medical equipment products.

3 disadvantages

The processing cost of shoveling fins is relatively high, and it generates a lot of waste and has a certain defect rate. When shoveling a long radiator, there will be a groove of about 4mm every 150mm in length.

4. Process capability

Maximum tooth width 800mm, tooth height 100mm, tooth pitch: (0.1mm-7.5mm), tooth thickness (0.1mm-7.5mm) tolerance +/-0.2mm

extruded heat sink

extruded heat sink Shovel heat sink

Shovel heat sink Cold forging heat sink

Cold forging heat sink Die cast heat sink

Die cast heat sink