Products

Product Description

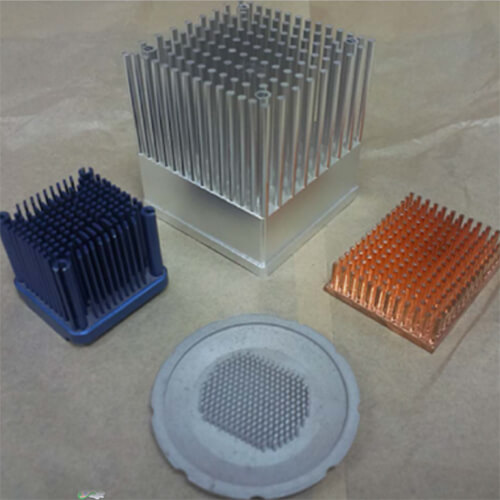

Cold forging heat sink

Features 1.

In production, the forging of the blank without heating is called cold forging. The cold forging materials are mostly aluminum, partial alloy, copper, low carbon steel, medium carbon steel and low alloy structural steel with small deformation resistance and good plasticity at room temperature.

2. Advantage:

Cold forging surface quality is good, high dimensional accuracy, can replace some cutting processing, high productivity and material utilization rate, low product cost, suitable for mass production of cold forging, can make metal strengthening, improve the strength of parts, the mechanical performance of the product is good.

3. The shortcomings

3.1 High mold requirements, high processing difficulty coefficient, long processing time, high cost: not suitable for small batch production:

3.2 High material requirements, materials usually need softening annealing treatment or surface phosphating lubrication treatment (cold forging heat sink mainly uses A1010 pure aluminum)

4. Process ability

900T machine, the largest product size :W250*L250mm*H150mm

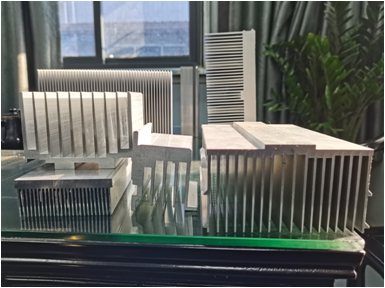

extruded heat sink

extruded heat sink Shovel heat sink

Shovel heat sink Cold forging heat sink

Cold forging heat sink Die cast heat sink

Die cast heat sink