Products

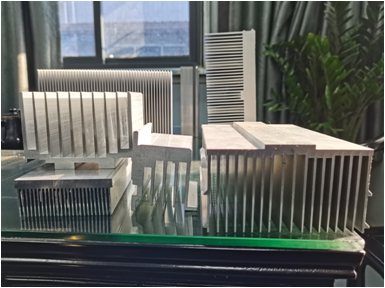

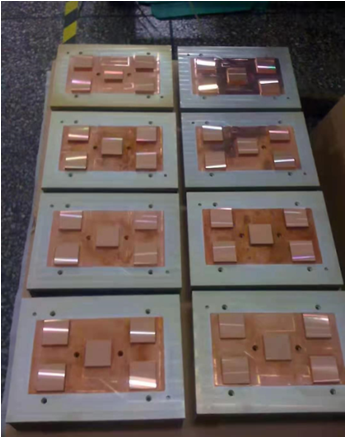

Medical equipment heat pipe radiator

The heat pipe radiator is divided into two parts: the base heat sink and the module heat pipe riveted heat sink. The base is made of aluminum heat sink or copper heat sink. The solid part is inserted into the solid part and buried with heat pipe and thermal paste to make it contact with heat quickly.

All heat sinks are made of aluminum. The number of leaf teeth is customized according to customer specifications. The aluminum leaf teeth transition from the surface to the root of the aluminum leaf teeth of the heat sink. A certain number of induction tubes are inserted and welded with another heat sink component to form a high-power heat pipe assembly radiator!

Send Inquiry

Product Description

Medical equipment heat pipe radiator

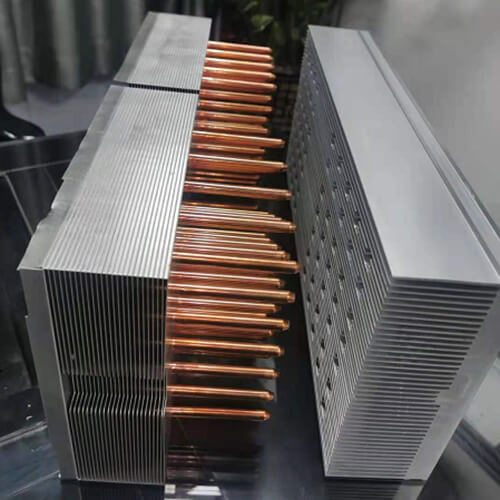

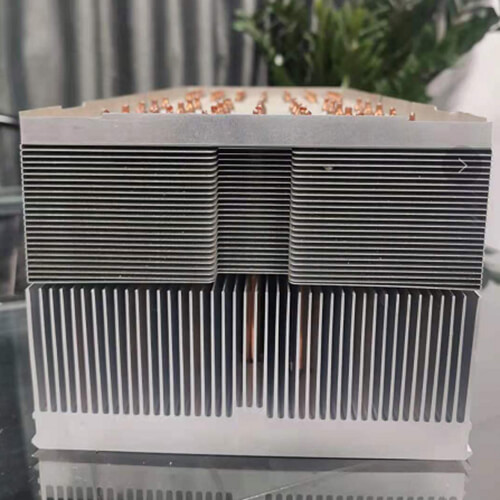

1. The characteristic module heat pipe radiator is divided into two parts: the base heat sink and the module heat pipe riveted heat sink. The base is an aluminum heat sink or a copper heat sink. The solid part of the bottom surface is also embedded with heat pipe and thermal paste to make it contact and conduct heat. Fast, the blade tooth surface is drilled with pipe holes or heat pipe slots that meet the number of heat pipes. The two parts are the required number of heat pipes and blade teeth after riveting to become a set of module blades and heat pipes. The radiator part is riveted. , In combination with the main body of the heat sink, insert the inside of the heat sink tube hole or the heat pipe groove, fill in the solder paste, and then increase the high temperature to make it into a whole.

2. Advantages The module heat pipe radiator has excellent heat conduction and heat dissipation effect. This is the best way for high-power heat pipe radiators. Often used in industrial equipment, medical machinery, aviation equipment and other fields!

3. Disadvantages The manufacturing process of module radiator products is costly, the number of copper pipes and heat pipes is large, there is a certain rate of failure, the processing time is long, and the blade tooth stamping die for the heat sink needs to be opened, the cost is high, and it is not suitable for mass production. Suitable for small batch production.

Hybrid copper-aluminum fin radiator

Hybrid copper-aluminum fin radiator High power heat pipe radiator

High power heat pipe radiator Medical equipment heat pipe radiator

Medical equipment heat pipe radiator