Products

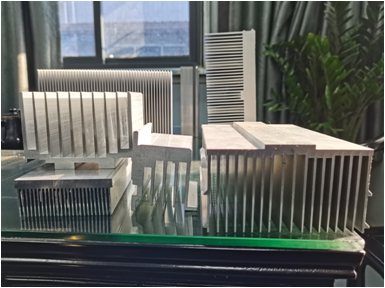

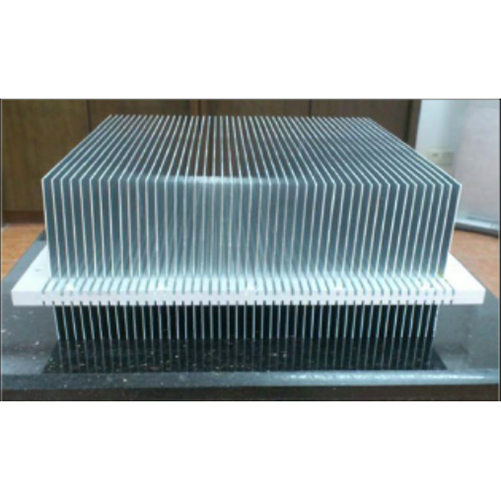

Stacked heat sink

The stacked radiator adopts glue-type solidified radiator. The heat dissipation method of this stacked radiator is usually aluminum blades or copper blades, which are fixed in the tool or the process of inserting the radiator by slurry or solder, and the entire radiator Place it on the heating pipe and let the stacked radiator become solidified. Become a whole radiator.

Send Inquiry

Product Description

Stacked heat sink

1. Features: The same as the current aluminum extruded heat sink field, it is impossible to break through the proportional limit of the blade thickness and length. Therefore, the stacked heat sink adopts a glue-type solidified heat sink. The heat dissipation method of this stacked heat sink is usually aluminum The density of the fins of the blades or paulownia blades are fixed in the grooves of the tool or the radiator using a guide paste or solder, and the integrated radiator is placed on the processing base to make the stacked radiator solidify into one overall.

2. Advantages of glued heat sinks break through the shortcomings in the field of extruded heat sinks, and the processing limitations of the blade thickness and length of the heat sink riveting process can produce higher density heat sinks. Different heat sink materials can be selected, Have some flexibility in MOQ

3, disadvantages

3.1 Using a heat sink combined with thermal paste and solder, the bottom of the blade will have interface impedance problems and poor heat dissipation performance.

3.2 Gluing is more dependent on labor costs, and product processing costs are higher

Bonded fin heat sink

Bonded fin heat sink Stacked heat sink

Stacked heat sink