Products

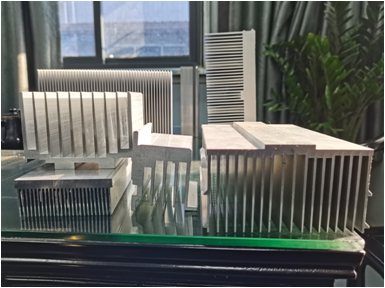

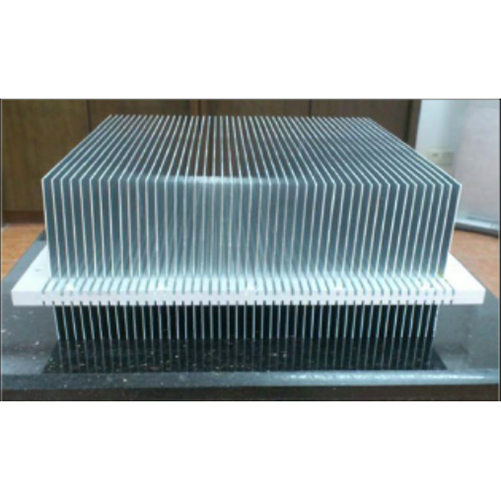

Bonded fin heat sink

Bonded fin heat sinks break through the short board in the field of extruded heat sinks, and the processing limitations of heat sink fin thickness and length in heat sink riveting and other processes can produce higher density heat sinks.

Send Inquiry

Product Description

Bonded fin heat sink

1. Features

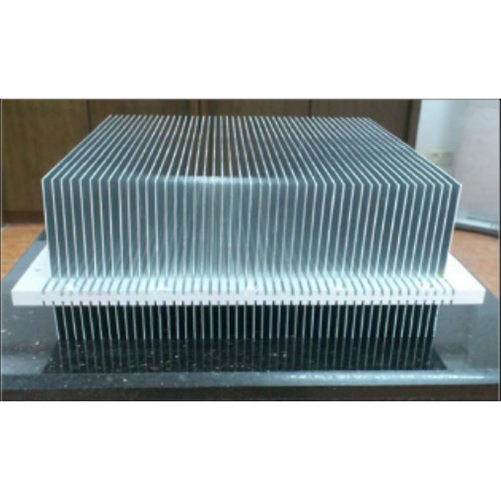

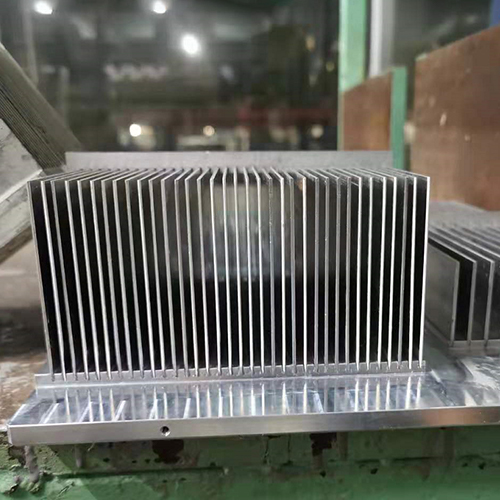

Same as the current aluminum extruded heat sink field cannot break through the limit of the ratio of blade thickness and length, so bonded fin heat sinks are used. This type of heat sink is usually made of aluminum heat sinks or copper heat sinks, using epoxy resin or solder, and The radiator and heat sink fins are fixed in a grooved tool, or in the groove processed by CNC machining, and the combined bonded fin radiator is placed on the heating base as a whole. Let the radiator and heat dissipation The piece is suspected to be a single individual radiator.

2. Advantages

Bonded fin heat sink breaks through the short board in the field of extruded heat sink. The processing limitations of heat sink fin thickness and length in heat sink riveting and other processes can produce higher density heat sinks. Different heat sinks can be selected. Fin material, with certain flexibility in MOQ

3. Disadvantages

3.1 Using a heat sink combined with epoxy resin and solder, there will be interface impedance problems at the bottom of the heat sink fin, and the heat dissipation performance is poor.

3.2 The epoxy resin relies on labor when bonding the heat sink fins, resulting in labor costs, and the cost of CNC machining of radiator products is relatively high.

Hot Tags: Insert heat sink, China, Customized, Manufacturers, Factory

Product Tag

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.

Bonded fin heat sink

Bonded fin heat sink Stacked heat sink

Stacked heat sink