Products

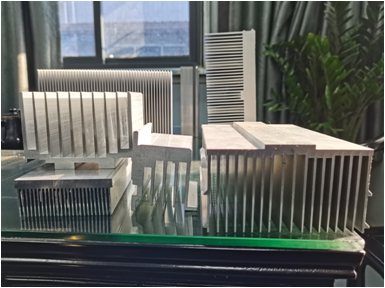

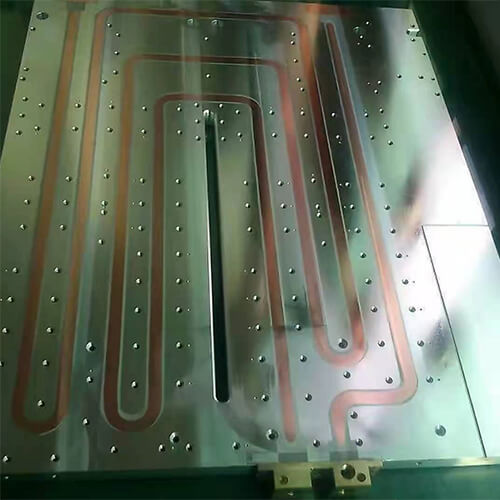

Water cooling plate radiator

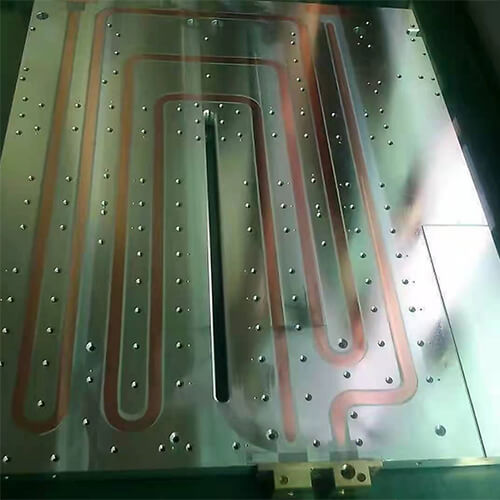

The water-cooled plate radiator is divided into two parts: the bottom plate and the pipe. The bottom plate can be copper/aluminum, and the pipe is generally copper pipe, and some stainless steel pipes are used. The corrosion resistance is good. The base is milled first, such as after installing the reserved pipe. Pull out the stainless steel from the groove, and press the heat pipe or stainless steel pipe into the CNC machined water-cooling plate base with a hydraulic punch according to the needs of the bending pipe. In the follow-up plastic surgery, filling.

Send Inquiry

Product Description

Water cooling plate radiator

1. The characteristic water-cooling plate radiator is divided into two parts: the bottom plate and the tube. The bottom plate can be copper/aluminum, and the tube is generally copper tube, and stainless steel tube is also used. Its corrosion resistance is better, and the base is milled with grooves. As a reservation for the later installation of the pipe, the stainless steel is cut to the required length, and after the pipe is bent as required, the pipe is pressed into the groove of the base with a hydraulic machine. The key to the quality of the product is the joint surface of the pipe and the bottom. Try to close it as far as possible to reduce the thermal resistance of the gap, and if necessary, apply thermal conductive glue (EPOXY) in the groove first.

2 Advantages It can give full play to the advantages of water cooling. In fact, the heat dissipation is better than air cooling, and it has the characteristics of quietness and fast heat dissipation.

3. Disadvantages The manufacturing cost of the product is relatively high. The installation and disassembly are more complicated. For example, the copper pipe has a high thermal conductivity, but its surface is easy to oxidize naturally, and the thermal conductivity of the stainless steel pipe is relatively low.

4. Process capacity 1000 length * width 550mm

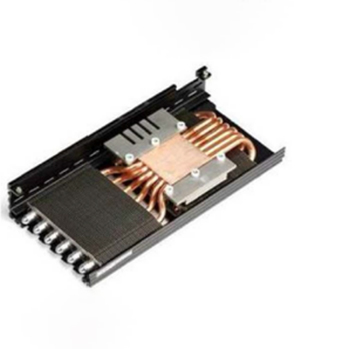

Heat pipe radiator

Heat pipe radiator Panel radiator

Panel radiator Water cooling plate radiator

Water cooling plate radiator Communication equipment radiator

Communication equipment radiator