Products

Taper turning in lathe machine

In the process of processing can be automatically measured, and can automatically compensate tool wear and other reasons for the error. So the processing quality is good, the accuracy is stable.

Send Inquiry

Product Description

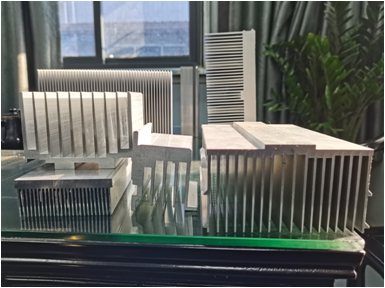

Taper turning in lathe machine

1. Advantages of CNC lathe by stepping motor drive ball screw transmission, because the ball screw can have interference, transmission without clearance, accuracy is mainly guaranteed by the machine tool itself and the program. In the process of processing can be automatically measured, and can automatically compensate tool wear and other reasons for the error. So the processing quality is good, the accuracy is stable.

2. Features can be programmed to turn out complex shapes, the ordinary lathe is difficult to process parts. Suitable for high precision, large batch, complex shape parts. But it also works well in small batches. It costs more to maintain than a common lathe.

3 shortcomings of the ordinary lathe by gear and ordinary screw nut drive. Because there is a gap between the motion pair, coupled with manual operation is not accurate, so the repetition accuracy is low. The measurement of the general lathe needs to stop after manual measurement, measurement error is large, and low efficiency. Suitable for batch small, precision requirements are not high, spare parts. The investment of CNC lathe is lower than that of CNC lathe, but it requires higher operating skills of workers, so the wage level is high. The scrap rate and productivity of a low level worker can give you a headache.

Taper turning

Taper turning Taper turning in lathe machine

Taper turning in lathe machine Lathe cutting

Lathe cutting