Products

Communication equipment parts processing

It can process complex surface which is difficult to be processed by conventional methods, and even some parts which cannot be observed.

Send Inquiry

Product Description

Communication equipment parts processing

1.CNC aluminum alloy processing characteristics

To greatly reduce the number of tooling, processing complex shapes of parts do not need complex tooling fixture. If you need to change the shape and size of the parts, you only need to modify the drawings of the parts, optimize the machining tool path and processing procedures to produce, suitable for the development of new products and model modification.

2. Advantages of CNC aluminum alloy processing

2.1 Stable processing quality, high processing accuracy, high repeated production accuracy, to meet the processing requirements of aerospace, military, electronic technology and other fields.

2.2 The efficiency is higher in the case of multi-variety, small batch and mass production, which can reduce the time of production preparation, machine adjustment and process inspection, and reduce the cutting time due to the use of the optimal cutting amount.

2.3 It can process complex surfaces that are difficult to process by conventional methods, and even some parts that cannot be observed.

3.CNC aluminum alloy processing defects

The disadvantage of CNC machining is that the cost of machine tool equipment is expensive, and maintenance personnel are required to have a higher level.

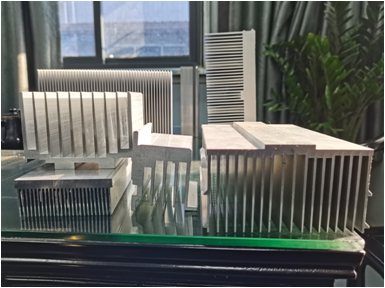

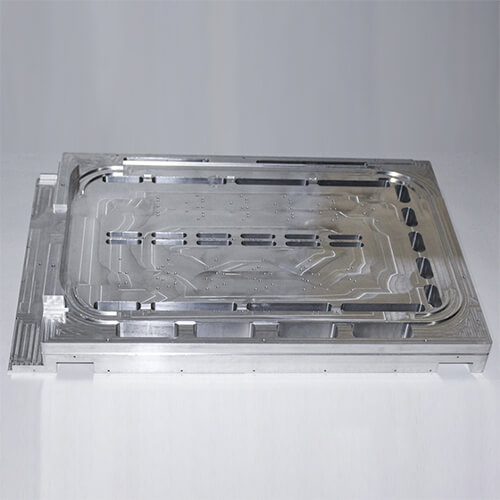

Cavity processing

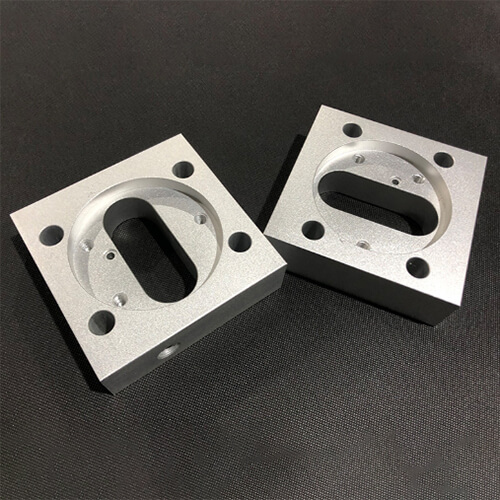

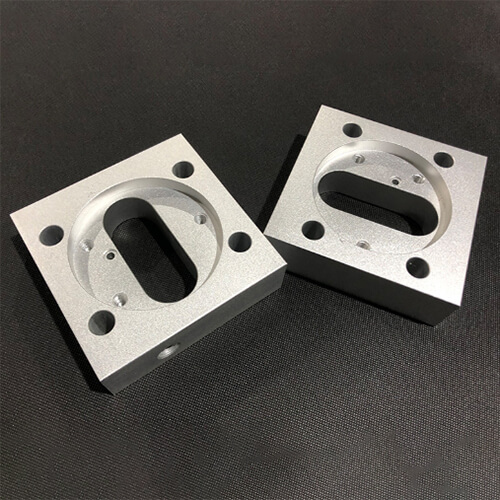

Cavity processing Communication equipment parts processing

Communication equipment parts processing Aluminum panel processing

Aluminum panel processing Aluminum alloy shell processing

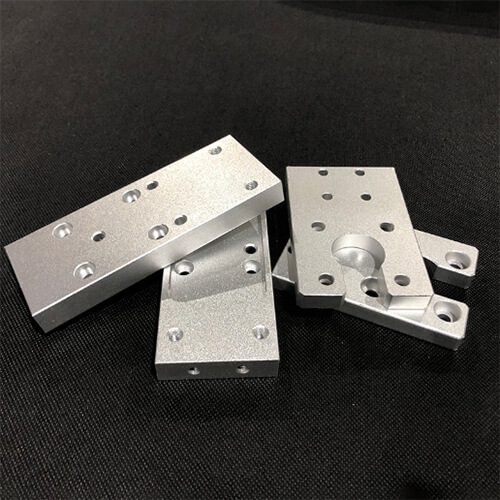

Aluminum alloy shell processing Aluminum bracket processing

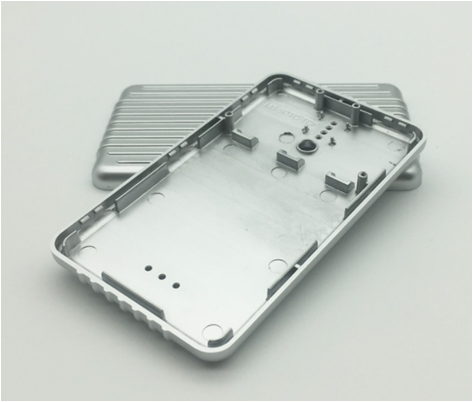

Aluminum bracket processing Aluminum alloy mobile phone case processing

Aluminum alloy mobile phone case processing